Actemium teams up with Ship Planner to enable data-driven sustainability

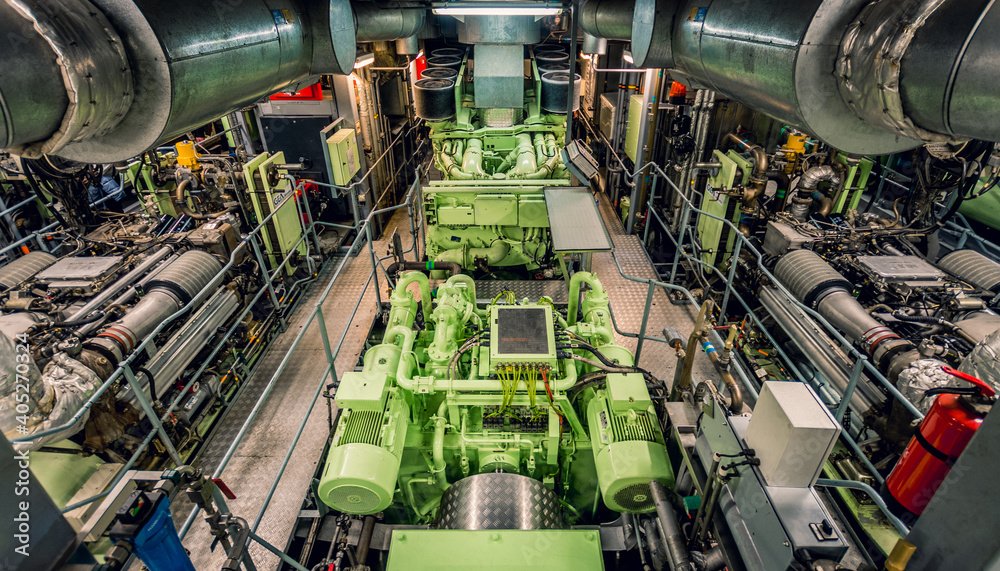

Cruise ships are like cities that navigate the seas. They need to store and deliver food and water, generate electricity and distribute it on a grid, provide air conditioning and heating and more.

All this comes on top of their core mission — safely sailing passengers and crew from place to place using fuel as efficiently as possible.

Modern cruise ships are equipped with sensors and computers to monitor all these systems to streamline operations, cutting costs and emissions — just like the factories and warehouses that Actemium equips. When ships are far from land, getting the data to the right places at the right time is tricky, so Actemium has teamed up with the tech company Ship Planner to serve shipping customers that need to optimize their IoT (Internet of Things) systems and the data they churn out.

Ship designers who became data engineers

Ship Planner is a Norwegian company whose founders have decades of experience designing ships and engineering their systems. It is a data company — focused on simplifying and optimising data integration on ships. The company lives by its plainspoken-yet-upbeat tagline: Making Sustainability Profitable.

The two companies’ roles in the partnership are clearly defined: Actemium uses its vast IoT experience to fit ships with cutting edge gear to keep an eye on water and fuel consumption, power distribution, engine wear, and dozens of other possible parameters. Ship Planner organizes the data aboard ship and securely sends it to engineers who use it to improve systems, or to authorities that require certain data.

Teaming up to provide turnkey solutions

“The key here is specialised knowledge,” said Jon-Ottar Ellefsen, head of Actemium’s maritime unit in Norway. “We know how to install the IoT systems quickly and efficiently, either in retrofit or on a ship under construction. Ship Planner has the expertise to make the data really work for the good of the customer — and the planet.”

Kristian Englund, founder of Ship Planner, agreed. “Both companies are really good at specific things that, when put together, form a real turn-key solution for the customer.”

Here are a couple of examples of what the companies have accomplished together:

- Norwegian Cruise Line managers identified a ship in their fleet for which they wanted a better understanding of onboard water consumption — as well as where and by whom the water was consumed. Actemium installed an IoT/software solution to monitor water consumption and organise it by sector: galleys, laundries, pools, etc. This provided NCL with the ability to finely tune and monitor water consumption on the ship.

- Data on fuel consumption, emissions, and other parameters needs to get to the corporate data center. Actemium and Ship Planner have created an easy-to-use solution that allows third-party systems to pick up bespoke data at any time. This enables the client to amplify its investment in data systems and create reporting systems that ease compliance with regulators.

Information contributes to sustainability

The Ship Planner technologies give our customers unmatched ability to really make an impact on CO2 emissions

Ellefsen said.

You can identify problems and continuously reshape the processes in the ship for improved sustainability.

Ship Planner handles a lot of the data right on-board ship, so the Chief Engineer can make well-informed decisions in a timely manner. “Getting timely, decision-critical data, regardless of the technology onboard, will contribute to saving fuel, while cutting costs and emissions,” Englund said. “We want to make it simple for the captain to know what he is consuming, what it is costing, and what the ships emissions profile is.”

The amount of time it takes to retrofit a ship is surprisingly small, Englund said. Using non-invasive technology and plug & play connections both for hardware and software systems, a team of two people can, under optimal conditions, set up an IoT system — with help from the sensor manufacturers — in less than a week.