Actemium Automates Two New E. Leclerc Distribution Centers

Early 2024, two E. Leclerc Distribution Centers selected Actemium Lyon Logistics to automate their fresh produce processing facilities. The Scacentre Distribution Center’s system will be operational in June 2025 as a result of many years of collaboration, trust, and shared experience with Actemium Lyon Logistics.

A Long-Standing Partnership

The relationship between Actemium Lyon Logistics and the Scacentre Distribution Center began in 2008 when Actemium teams carried out a retrofit project on a Distribution Center’s system originally installed by a competitor. Since then, various projects have been completed together to upgrade the facility’s equipment. Following the Covid-19 period, the Distribution Center had the opportunity to relocate its fresh produce processing operations in a larger building with a total area of 15,000 m² (of which 8,000 m² is dedicated to fresh produce). In early 2024, the Scacentre Distribution Center once again entrusted Actemium Lyon Logistics to install its new automated system.

A Promising Project for Supplying Regional Sales Outlets

The goal of this new automated facility is to receive and sort a variety of fresh, fragile products, sometimes containing liquids, and then dispatch them to hypermarkets, supermarkets, and small retail outlets in the region according to their supply needs.

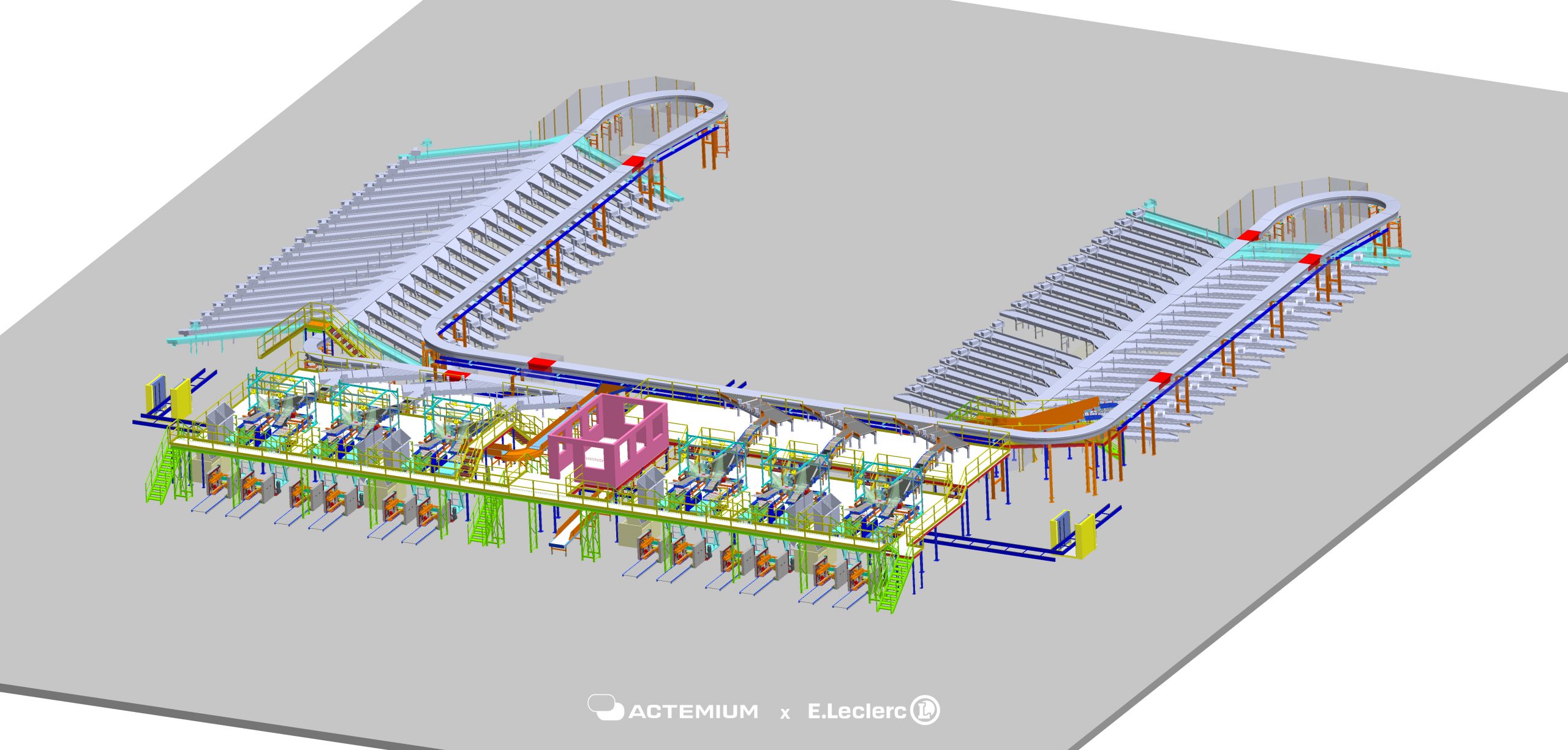

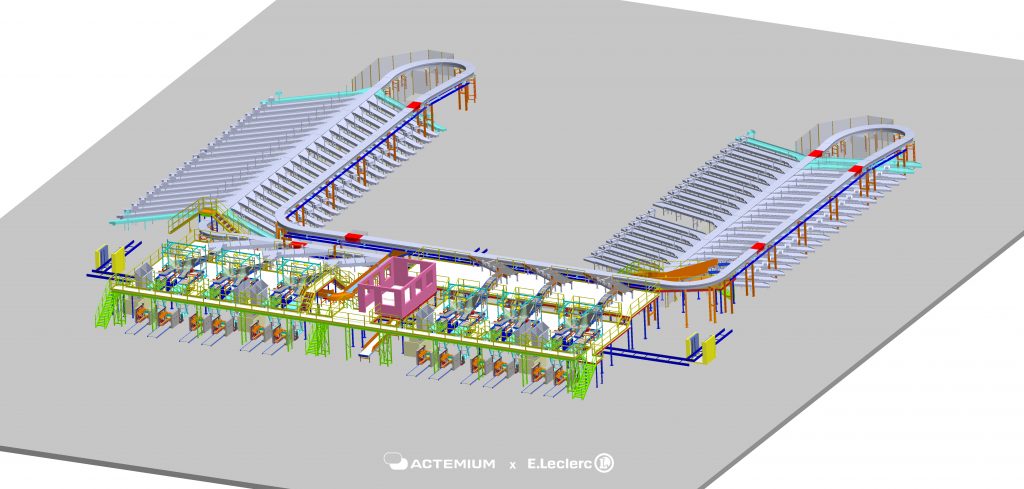

The selected solution consists of 6 injection stations, sized to process an average of 950 packages per hour, where operators manually deposit the products from their ergonomic workstations. On the dispatch side, the sorter can process up to 7,200 packages per hour and serves 88 outlets for hypermarkets and supermarkets in the region and 12 outlets for small retail outlets.

Regarding the system control, which is the real heart of the facility’s intelligence, Actemium Lyon Logistics has integrated its WCS (Warehouse Control System) software. This SpeedSort WCS makes it possible to edit sorting plans, manage the barcode and customer references database, the complex sorting algorithm and serves as the interface for uploading sorting reports. Currently, Actemium Lyon Logistics teams are in the project study phase for a deployment on site planned from January 2025. Commissioning is scheduled for June 2025.

A Customised and Flexible Solution to Anticipate Growth

The stores in the Scacentre’s geographical area are developing, and the volumes of fresh products being handled are growing rapidly. The installation of a sorter will allow us to support the growth of our stores in the coming years while limiting the need for space. It will also improve the working conditions of our employees and the quality of service provided to the stores.

explains Benjamin Chabalier, Director of Scacentre.

The Actemium Lyon Logistics teams are very attentive and creative. This makes it possible to adapt the solution in detail according to our constraints and our organizational wishes.

A similar solution already has been selected to automate a second E. Leclerc Distribution Center, differentiating from the first one as it will enable the customer to significantly increase its fresh product activity for the supply of regional sales outlets and to reduce pallet preparation errors while addressing operator recruitment issues.