Ardex builds a complete new mixing plant in Australia with Actemium

Ardex, a family owned company founded more than 70 years ago, is a global leader of high performance products for construction. Thanks to its presence in more than 50 countries and representing 20 major brands, Ardex operates through its 68 subsidiaries and 50 production facilities over 5 continents. Their product range includes technical mortars for tiles & stones, flooring, repair screeds, a full set of renders, waterproofing and many others. Thanks to its technical expertise and its cutting edge products, Ardex provides innovative solutions to some of the most prestigious building projects around the world.

After a first successful collaboration for a turnkey mixing tower in Brisbane, Australia, Ardex and Actemium Saint-Etienne Process Solutions – Sofraden are scaling up their partnership with the design, supply, assembly and commissioning of a major production plant in Sydney, Australia. The aim of the project is to consolidate several storage and production premises in one unique location, at the premium estate THE YARDS, Kemps Creek, New South Wales.

Genesis of the project

After initial discussions in 2018, the project specifications stage started in 2021. A close cooperation, in collaboration with the main contractors, over 2021 and 2022 led to the development of the final design. This allowed Ardex to obtain the development Approval from the regulatory authorities.

“We thank Ardex for its constructive approach during this early phase of the project. Our close working relationship with the whole team in Australia and with Corporate Engineering resulted in an effective collaboration built on trust”

says Nicolas Genevrier, Actemium-Sofraden Sales Manager.

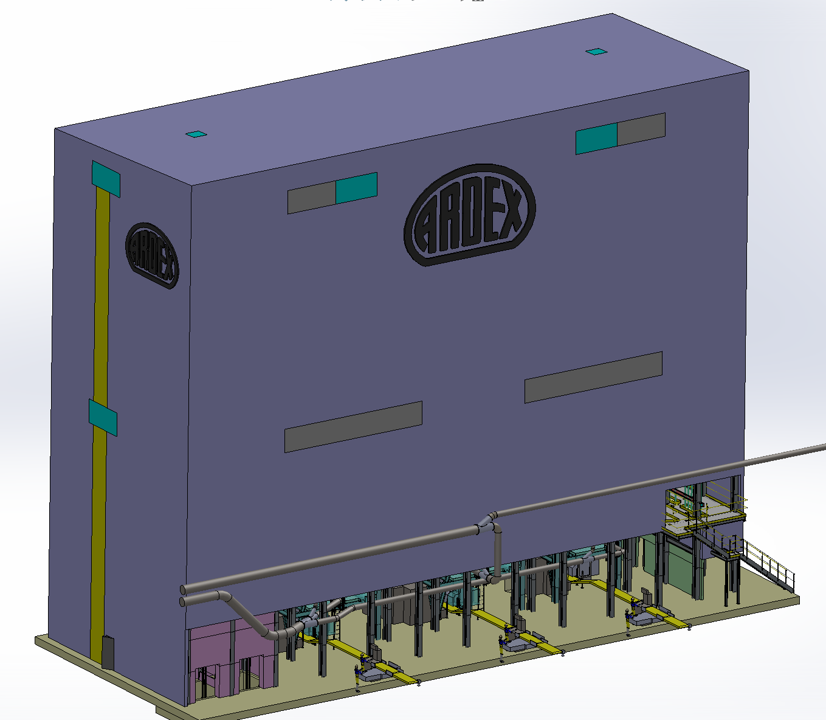

The solution itself

The production facility for dry-mix products is designed according to the vertical principle. The 35 meter high tower incorporates 3 complete mixing lines, including the storage and automatic dosing of more than 35 materials, from the raw materials to very specific and sensitive chemicals. A specific design avoids cross-contamination between different formulas and reduced time and ease of cleaning the equipment when required.

3 MIB Sofraden mixers with their CIP (Clean In Place) systems are at the heart of the solution. The use of the latest chopper designs on the mixers, in partnership with Ardex, will handle sticky and clogging materials in a proper, safe and efficient way.

Production is managed by Prodose® Software, as in 3 other Ardex plants, and 24/7 remote helpdesk is part of the package. The installation also complies with local Australian and New South Wales standards.

Main milestones

The manufacturing of the main equipment has already started for the first on site deliveries by the end of 2023. Erection of the plant will start in January 2024 and will last for almost one year including the testing and commissioning of the 3 lines. For On-site work, the use of an intermediate storage area for large items, is planned to avoid site congestion during this period. In order to accompany the customer on its production ramp-up, 2 on-site assistance and training periods are foreseen after start-up.

The Actemium-Sofraden teams are extremely proud to continue their partnership with Ardex in the implementation of this major project.