High-Speed Sensor Assembly for the Automotive Industry

Driven by market requirements, a major player in the automotive industry specializing in advanced technologies required a new automated machine capable of assembling sensors into two models of plastic carriers.

The new machine needed to assemble one sensor every 8 seconds and maintain an availability rate of 98%. The second key component of this machine is the LinMot® high-speed magnetic linear actuator, which translates the carrier after the metallic strip separation to the assembly tool.

A Turn-key Solution

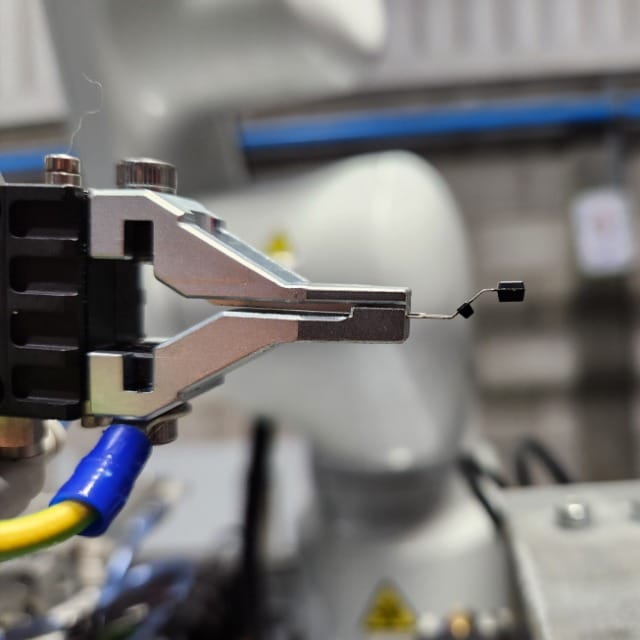

Actemium Mexico took on the challenge and designed, built, assembled, and delivered a state-of-the-art automatic machine. The operator’s task is to refill sensors and carrier strips and initialize the machine. The equipment automatically feeds one sensor at a time, which is then handled by a robot and taken directly to the assembly tool. Simultaneously, the machine feeds a carrier to the cutting machine, places it in the translation nest, and moves it to the assembly tool. The machine operates at the desired cycle time and exceeds the 98% technical availability requirement.

Major Results and Future Implications

As the automotive industry continues to evolve, solutions like these will play a critical role in driving efficiency and maintaining high standards of production quality. This successful implementation not only highlights the capabilities of modern technology but also sets a benchmark for future advancements in automated manufacturing.