Know-How

At Actemium, we bring extensive expertise to the automotive industry, covering design, feasibility studies, flow simulations, life cycle analysis, and FMEA for reliability and maintainability. We excel in project management, providing coordination, cost control, time planning, and sub-contract management. Our services include site installation, commissioning, and robust multi-technical maintenance. Actemium’s electrical and mechanical solutions encompass high and low voltage systems, automation, software, component purchases, subcontracting, manufacturing, testing, and robot programming.

Our solutions

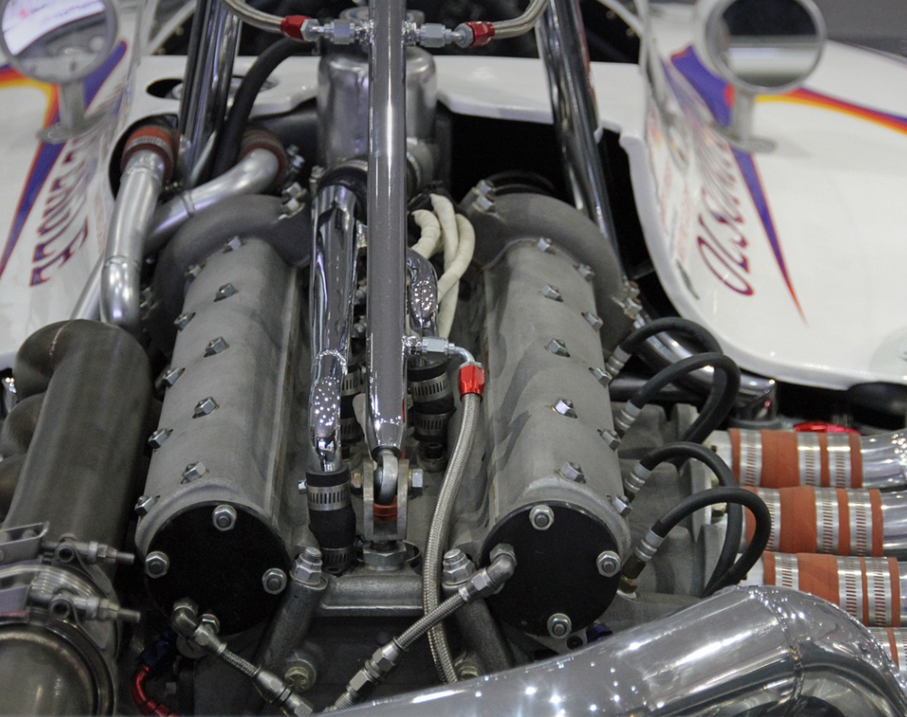

We enhance automotive production with efficient handling and flow systems, including motorised roller beds and conveyors. We manage new stamping lines, robotic handling, layout modifications and revamping. Body in White solutions developed by our teams feature assembly lines, welding systems, and handling systems. In the paint shop, we provide primer and lacquer chambers, ovens, and robot-assisted processes. Actemium’s powertrain solutions cover machining, assembly, and test systems. For final assembly, we offer marriage systems, tooling, picking systems, trackside stations, and electronic diagnostics. Actemium also specialises in plant relocation and machinery for Tier One suppliers.

Connect with Actemium's Experts

If you have questions or want to acces to our service click here!