Paper is essential in our daily lives, spanning from books and newspapers to packaging and hygiene products. For over four decades, Actemium has been a leader in engineering and integrating tracking and control solutions to optimise energy and information flows in the paper manufacturing process.

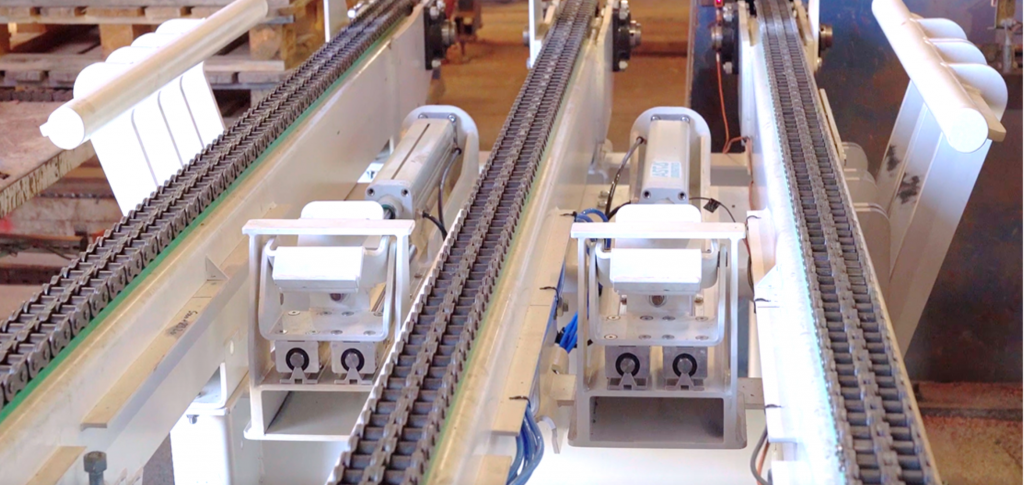

Our comprehensive solutions cover energy management, automation, electrical engineering, electrical installation, instrumentation, and hydraulic systems throughout the entire manufacturing process. From stock preparation plants to the drying section and calendar stack, Actemium ensures efficient and seamless operations in the wood and paper industry.

Actemium’s Expertise

At Actemium, we offer specialised expertise tailored for the wood and paper products industry, providing comprehensive solutions to enhance efficiency and operational reliability.

- Consulting Services: From feasibility studies to ROI assessments, Actemium provides strategic consulting to optimise system architecture and operational processes.

- Material Engineering: We excel in developing detailed wiring diagrams, conducting cabling studies, and producing assembly and loop diagrams to ensure seamless integration and performance.

- Construction of Electrical Cabinets: Actemium designs and builds electrical distribution panels, specialised cabinets for hydraulic and pneumatic systems, and control desks to meet industry-specific requirements.

- Maintenance Solutions: Our services include remote maintenance capabilities available 24/7, comprehensive documentation support, and proactive maintenance strategies to minimise downtime.

- Basic Engineering: We specialise in creating control and instrumentation diagrams, compiling equipment lists, defining technical specifications, and managing equipment procurement missions for efficient project execution.

- Software Engineering: Actemium designs and integrates systems, develops functional diagrams, and ensures seamless integration of external systems and MES (Manufacturing Execution Systems) for optimised production workflows.

- Assembly Expertise: Our capabilities span electroassembly and instrumentation, assembly of hydraulic and pneumatic systems, and centralised lubrication systems installation to enhance operational efficiency.

- Software Library: Benefit from Actemium’s enriched library for the Siemens PCS7 control system—MFL (Modular Flexible Library)—ensuring high programming quality and system reliability for paper manufacturing processes.

Trust Actemium for innovative solutions and expertise that optimise productivity and reliability across the wood and paper products industry.

Connect with Actemium's Experts

If you have questions or want to acces to our service click here!